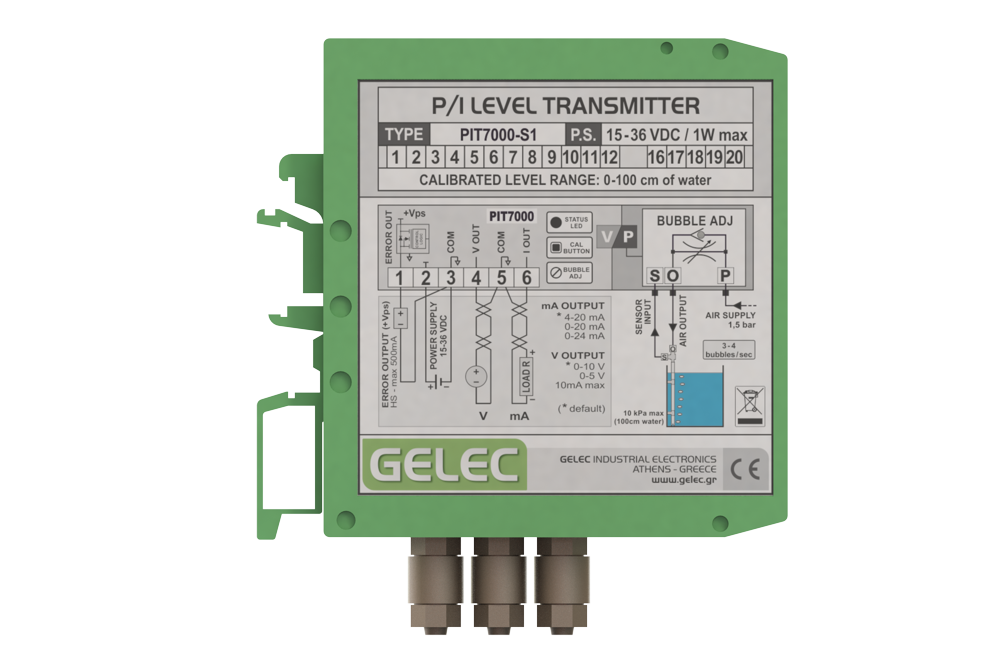

The PIT7000 is an industrial, rangeable pressure transmitter, suitable for hydrostatic level measurement in open or vented tanks. It converts the level-proportional hydrostatic pressure to linear current and voltage signal standards (4-20, 0-20, 0-24mA / 0-5, 0-10V) for further processing.

The two output signals can be utilized simultaneously or independently, while their respective output range is selected through a dip-switch. PIT7000 zero and span settings can be easily rescaled in order to meet the operating requirements of your application, while factory default settings can be restored at any time.

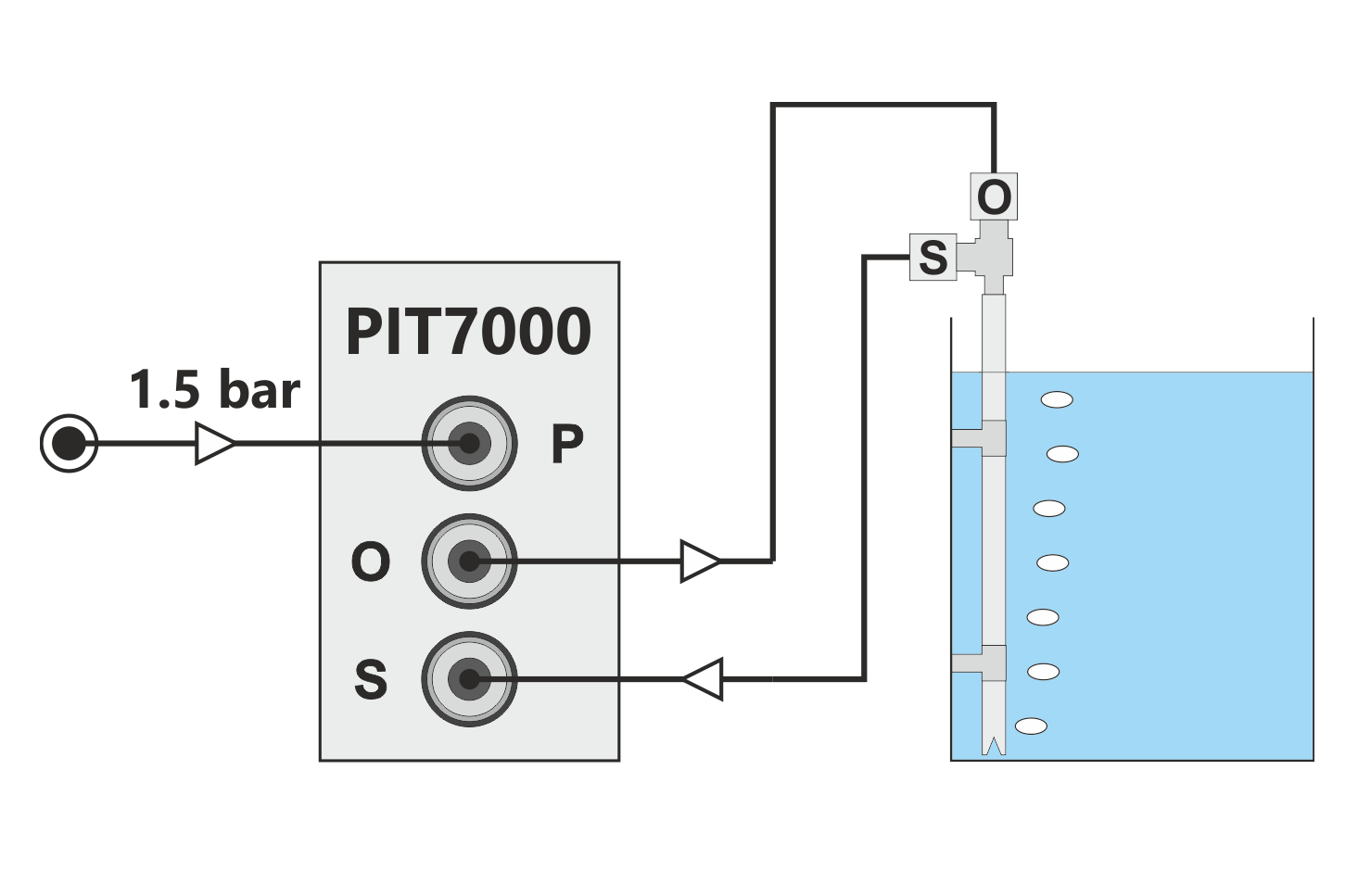

The system requires the installation of a bubble tube submerged in the measured fluid, properly connected to the transmitter with pneumatic tubes. A volume of compressed air is constantly released into the fluid in a form of bubbles through the device’s airflow regulator and the bubble tube. As the level changes, the backpressure measured by the transmitter’s gauge pressure sensor is a direct level measurement.

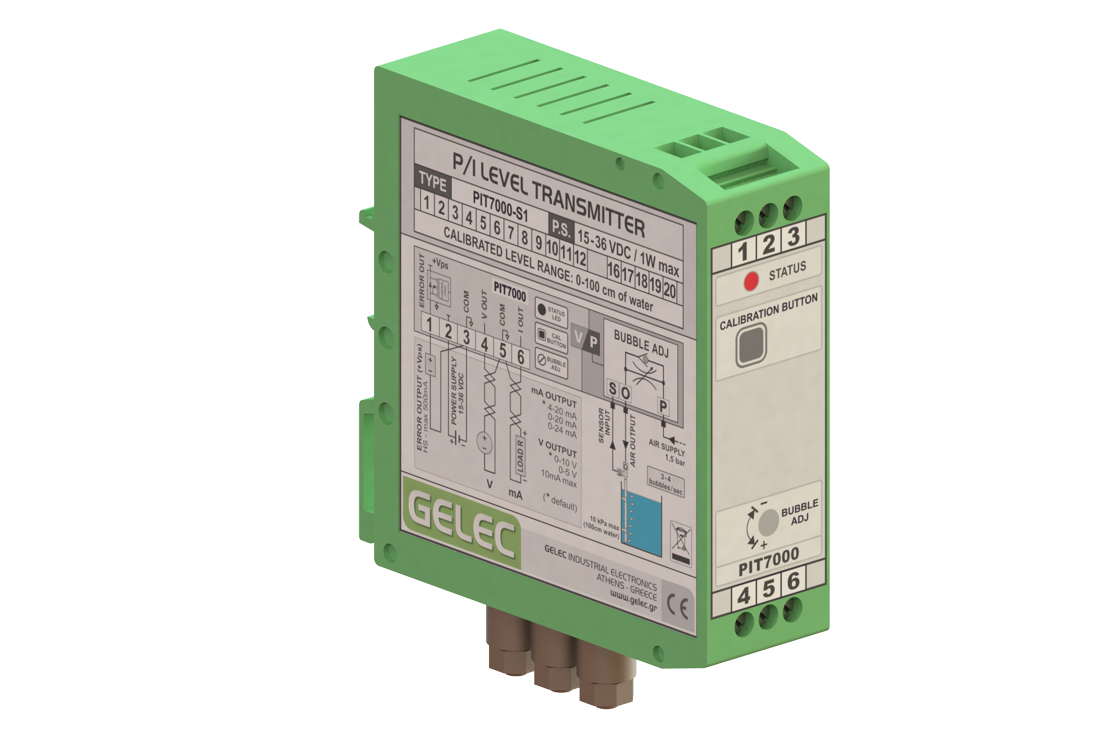

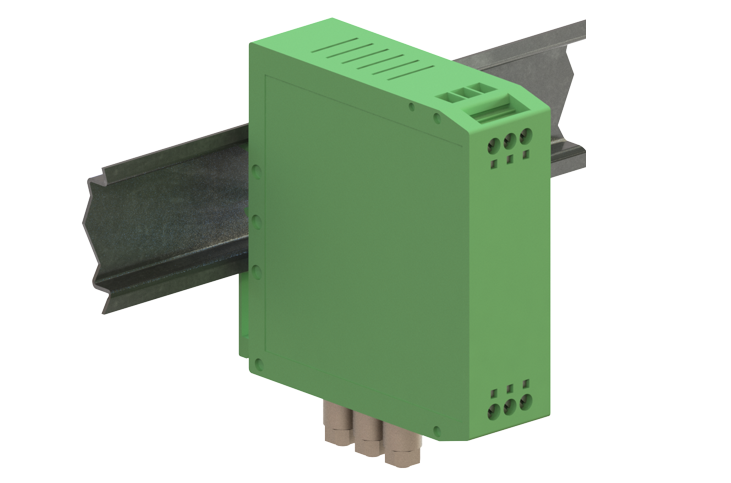

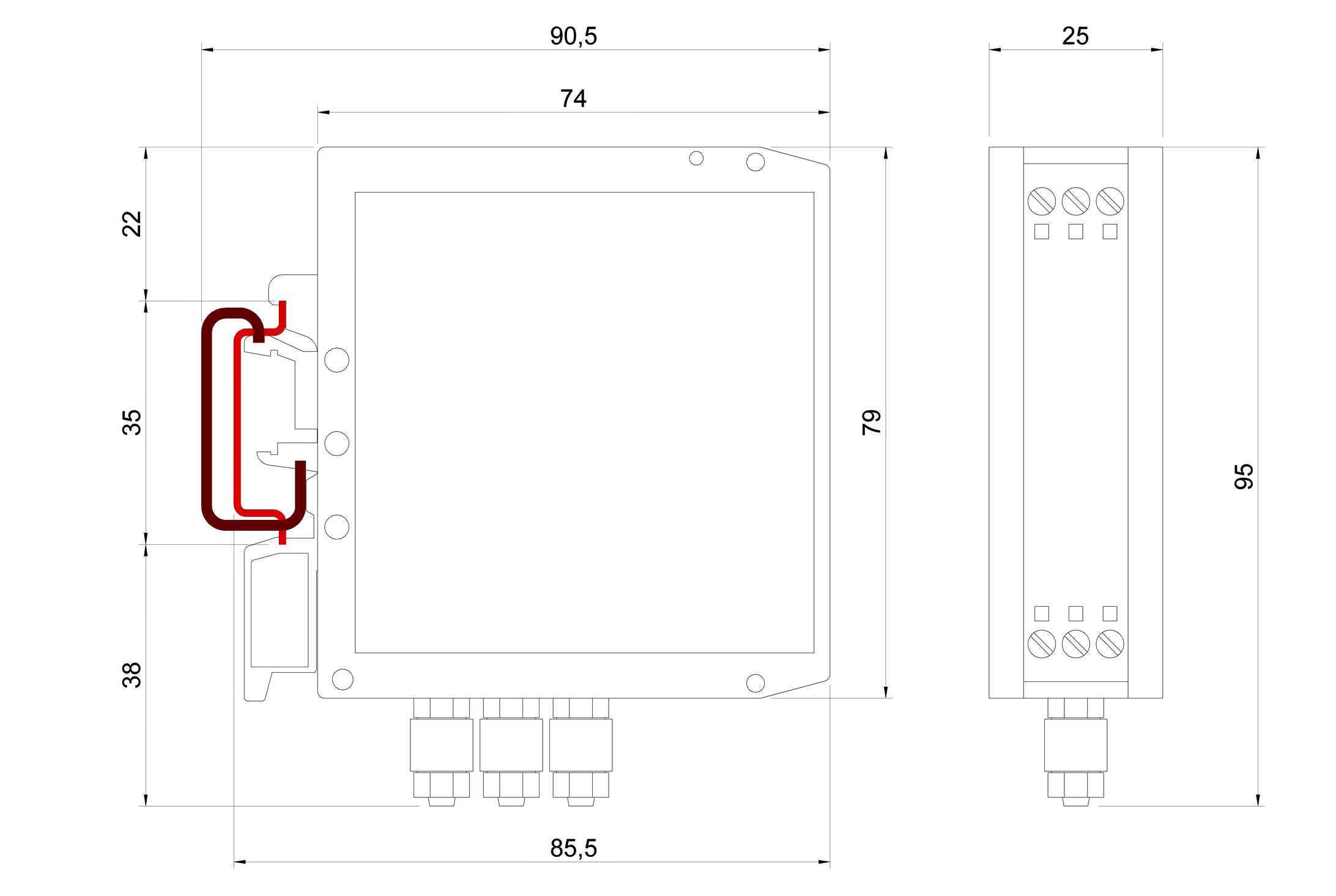

The transmitter is isolated from the vessel’s area and includes a gauge type pressure sensor, an airflow regulator with pneumatic adaptors, a calibration button and a status LED. It is designed to be installed inside an electrical control panel, snapped onto commercially available DIN mounting rails (NS32/NS35). The thermoplastic housing (Polyamide PA 6.6) is suitable and approved for electronic devices and industrial environment.

Features

|

|

Advantages of Bubbler Systems

|

|