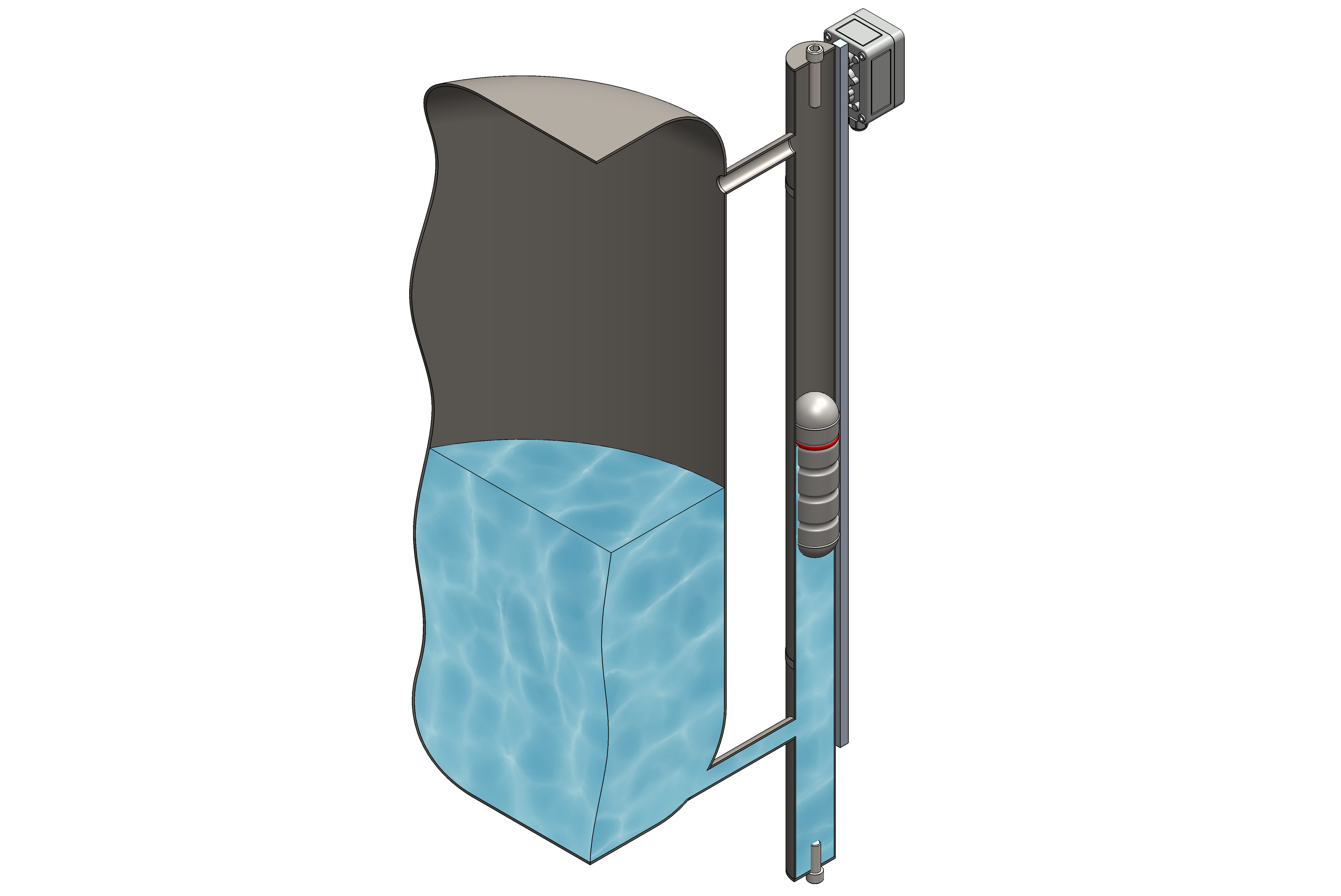

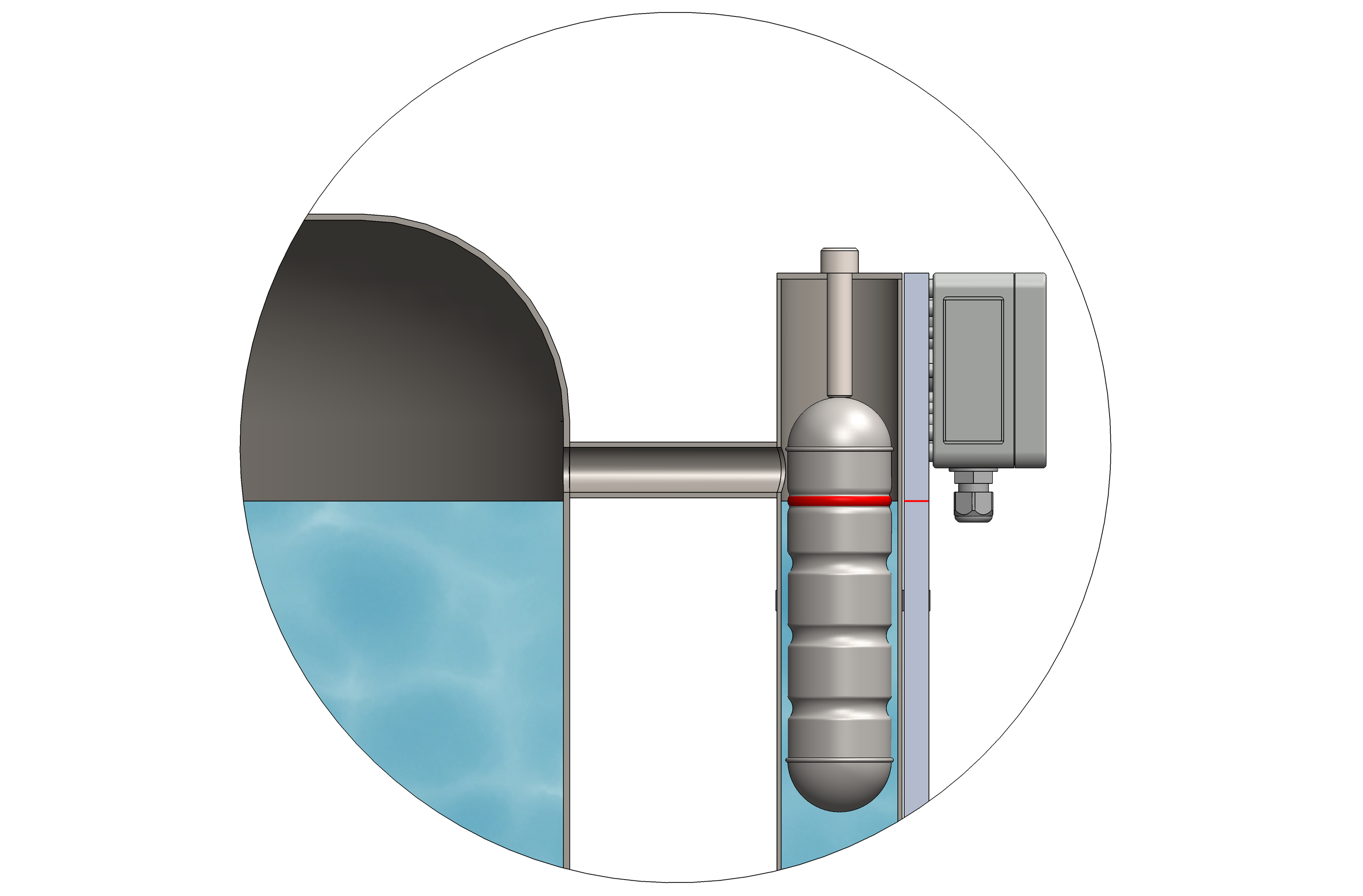

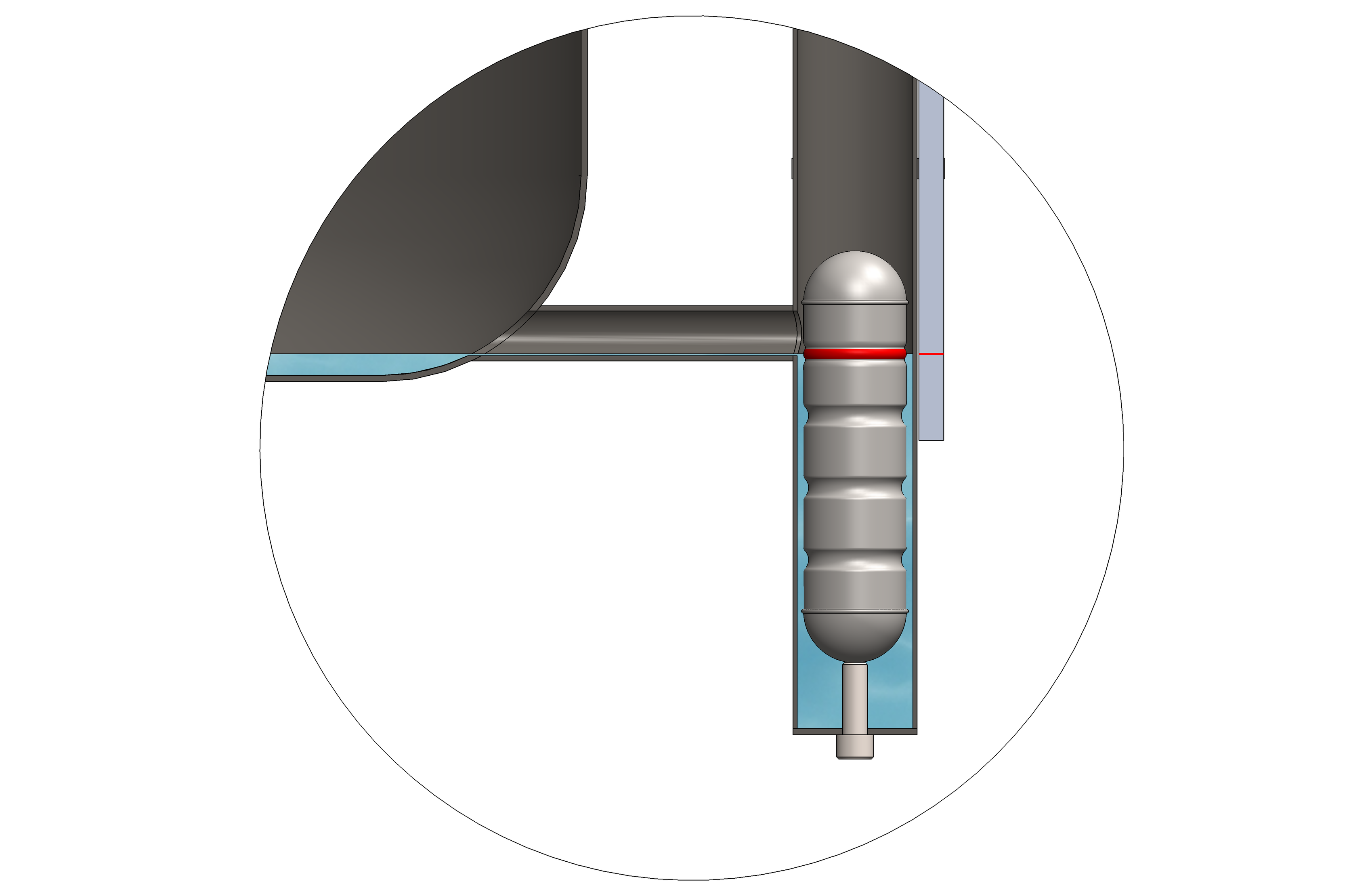

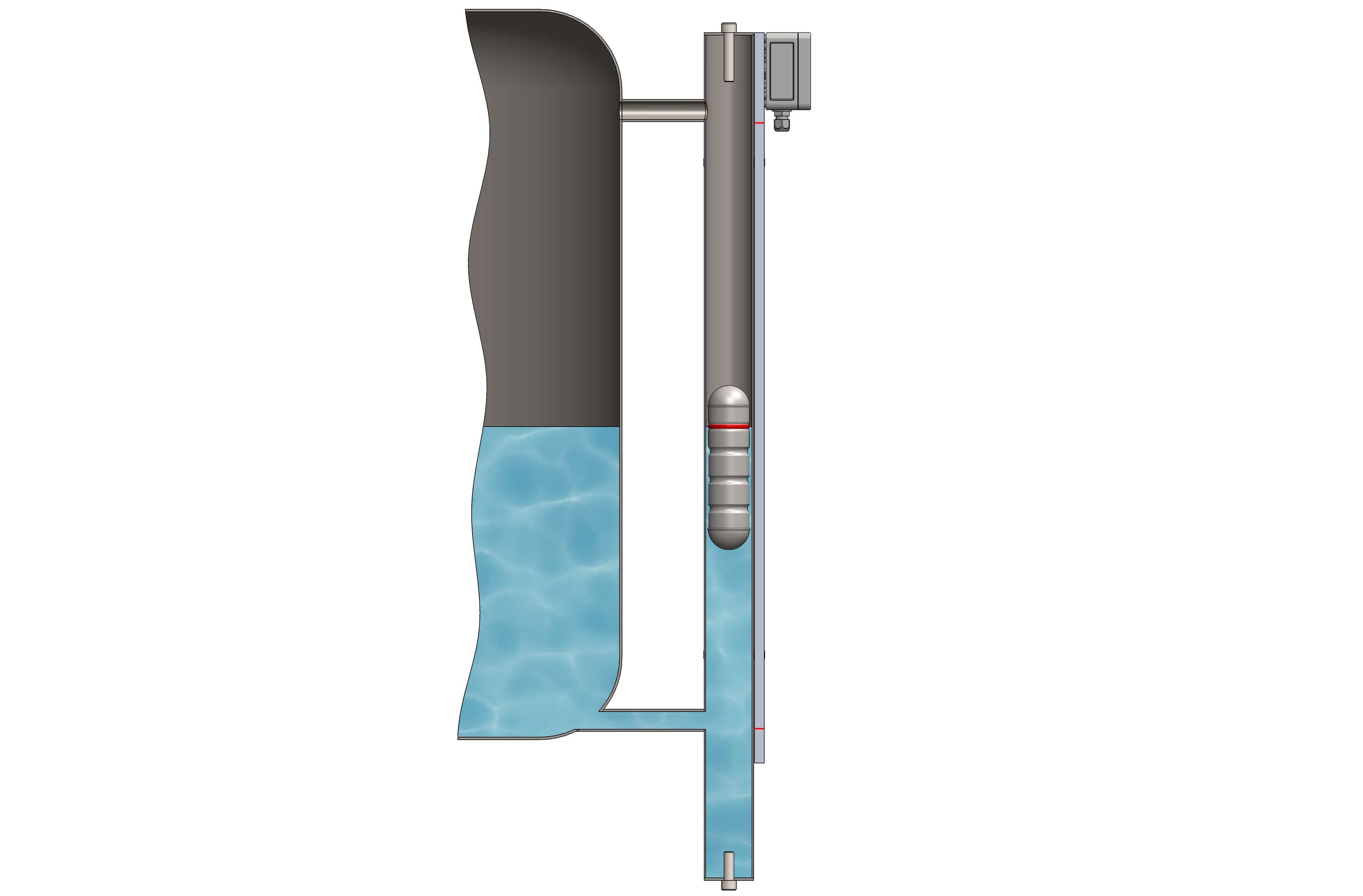

The LTR7000 is an industrial, rangeable resistive chain level transmitter, suitable for non-invasive level measurement in open or closed tanks. Its operation is based on the magnetic floating principle and communicating vessels.

A magnetic float inside a measuring chamber mounted to the application tank, follows the fluid level changes during process. Having an array of closely spaced hall effect sensors, the LTR7000 senses the float’s position and therefore the height of the fluid level. It provides a continuous, linear current and voltage output signal (4-20, 0-20, 4-21mA / 0-5, 0-10V), proportional to the level height and available for further processing.

The two output signals can be utilized simultaneously or independently and their respective output range is selected through a dip-switch. LTR7000 zero and span settings can be easily rescaled in order to meet each application’s operating requirements, while factory default settings can be restored at any time.

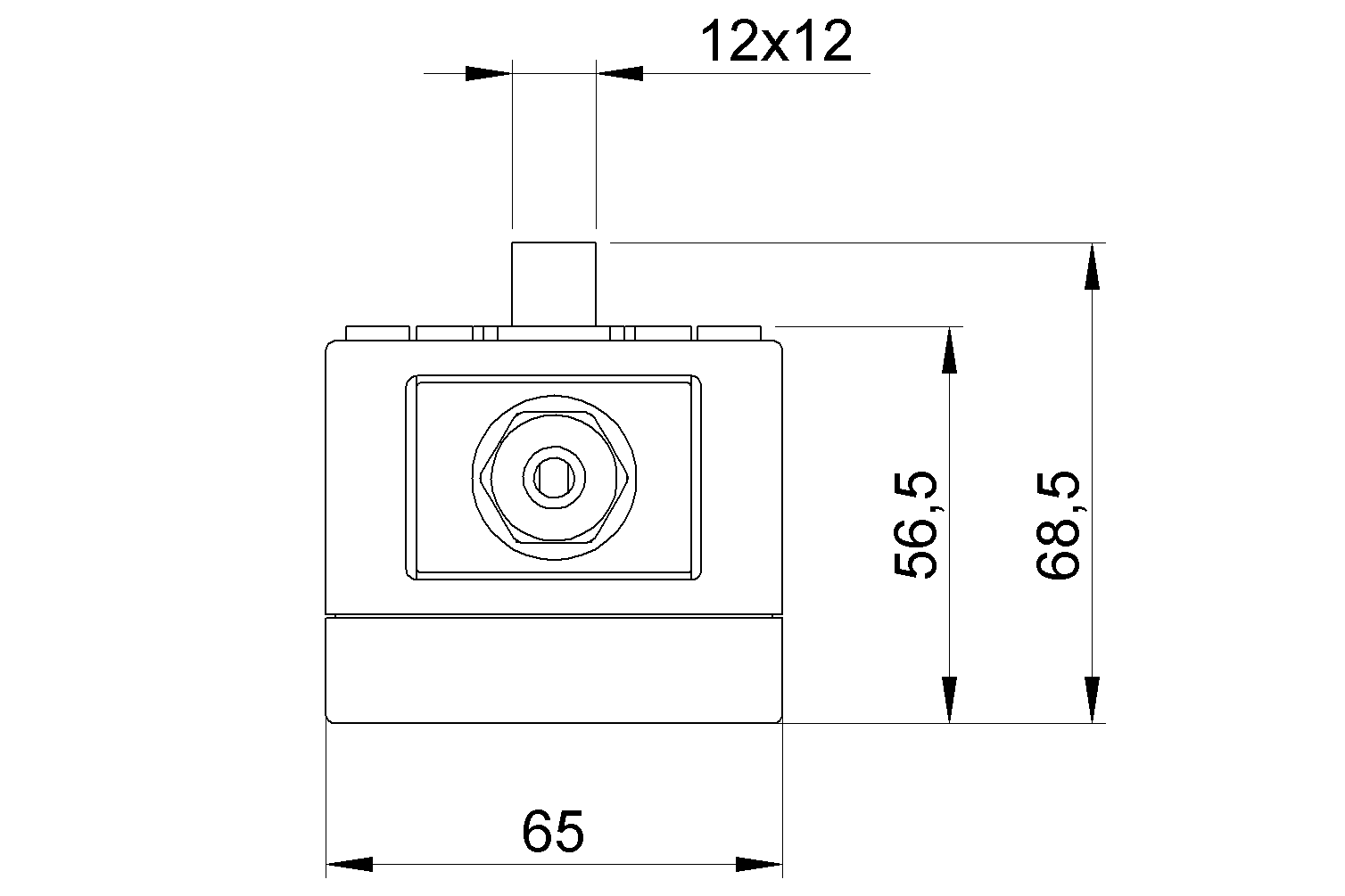

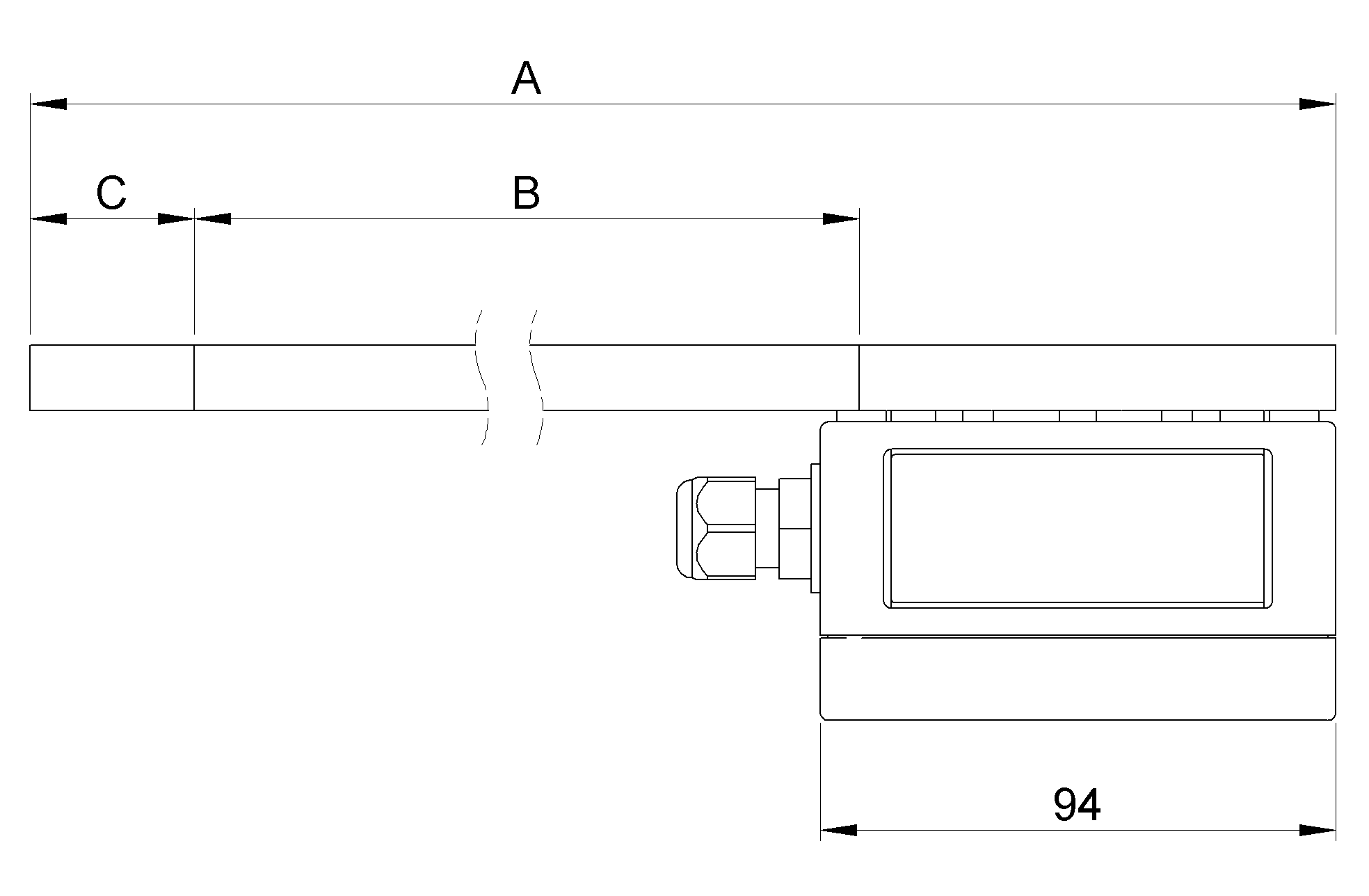

It consists of a stainless-steel square tube which incorporates the sensor chain and a fiberglass reinforced polycarbonate enclosure, including the microprocessor based transmitter and the connection terminal block.

With 7mm sensing resolution and a variety of standard analog signals that can be assigned by the user to any level range up to 205cm, the LTR7000 is an ideal solution for industrial, heavy-duty level measurement applications.

Features

|

|

Advantages

|

|