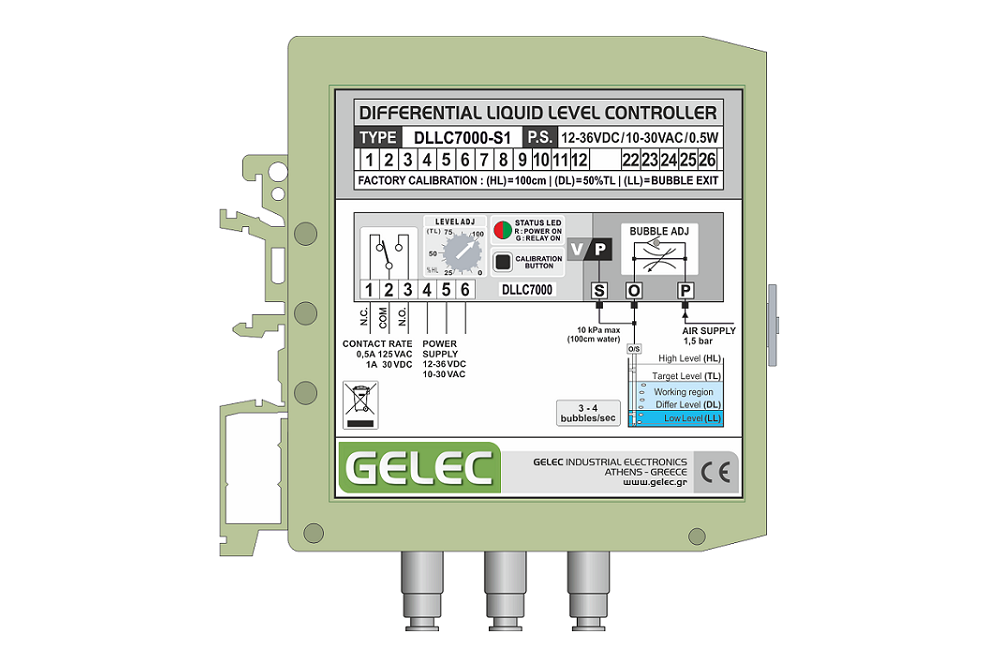

The DLLC7000 is a programmable, rangeable device used for liquid level control within a desirable region, in open tanks of height from 10cm up to 500cm, with analog sensor and digital output. Its operation is based on the measurement of liquid’s hydrostatic pressure.

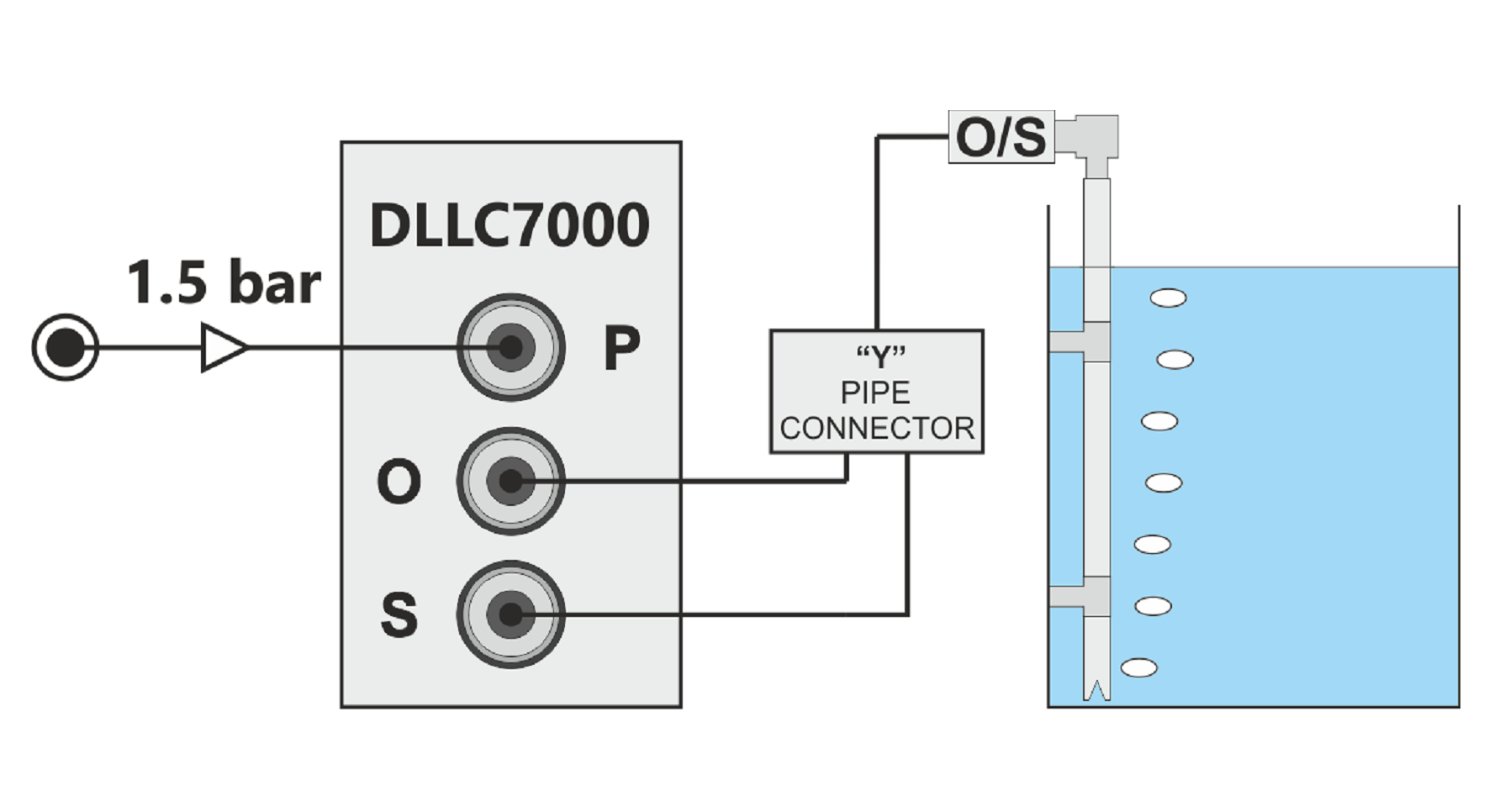

The system requires the installation of a bubble tube submerged in the measured fluid, properly connected to the device with pneumatic tubes. A volume of compressed air is constantly released into the fluid in a form of bubbles through the device’s airflow regulator and the bubble tube.

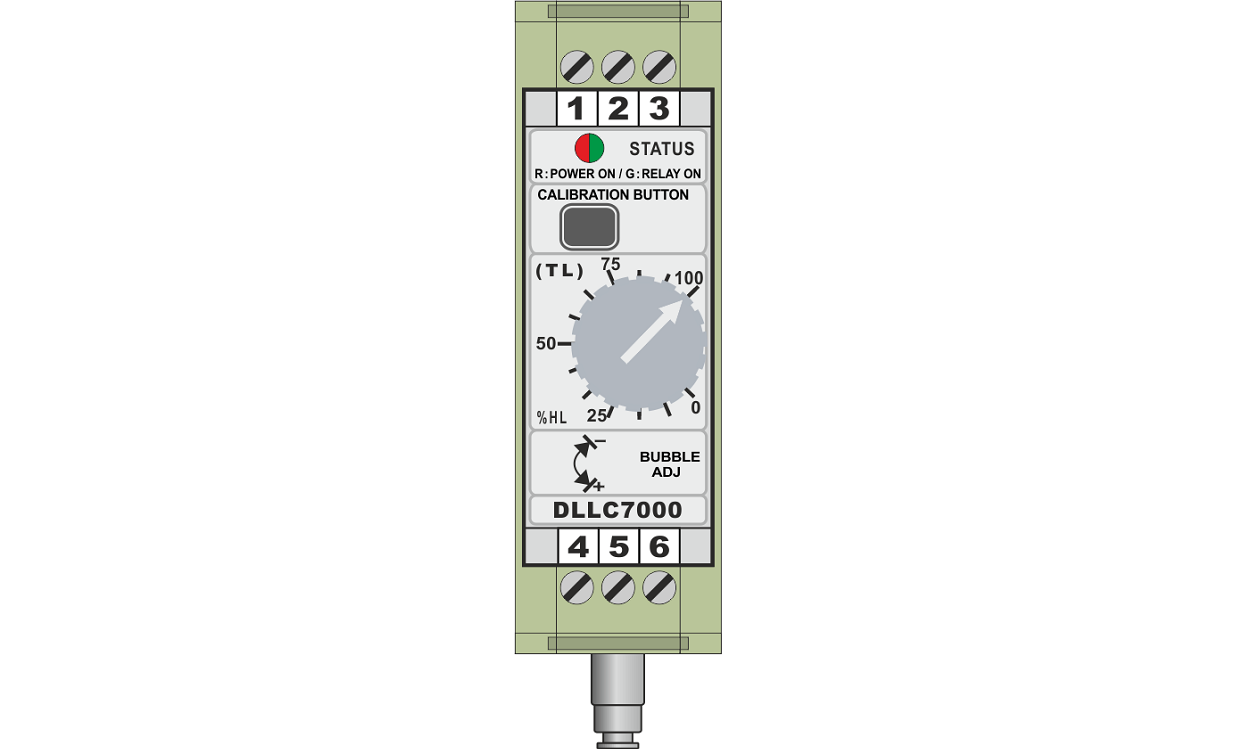

As the level changes, the backpressure measured by the device’s gauge pressure sensor is a direct level measurement. Several electronic circuits and a microcontroller process this signal and depending on user adjustments, a digital command occurs when the tank liquid reaches the selected Target Level. The outcome is the fluctuation of the level within a desirable working region (between Target Level and Differential Level).

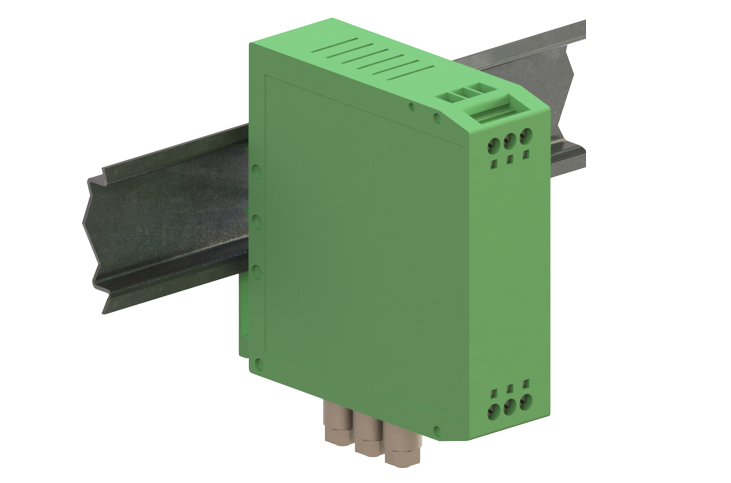

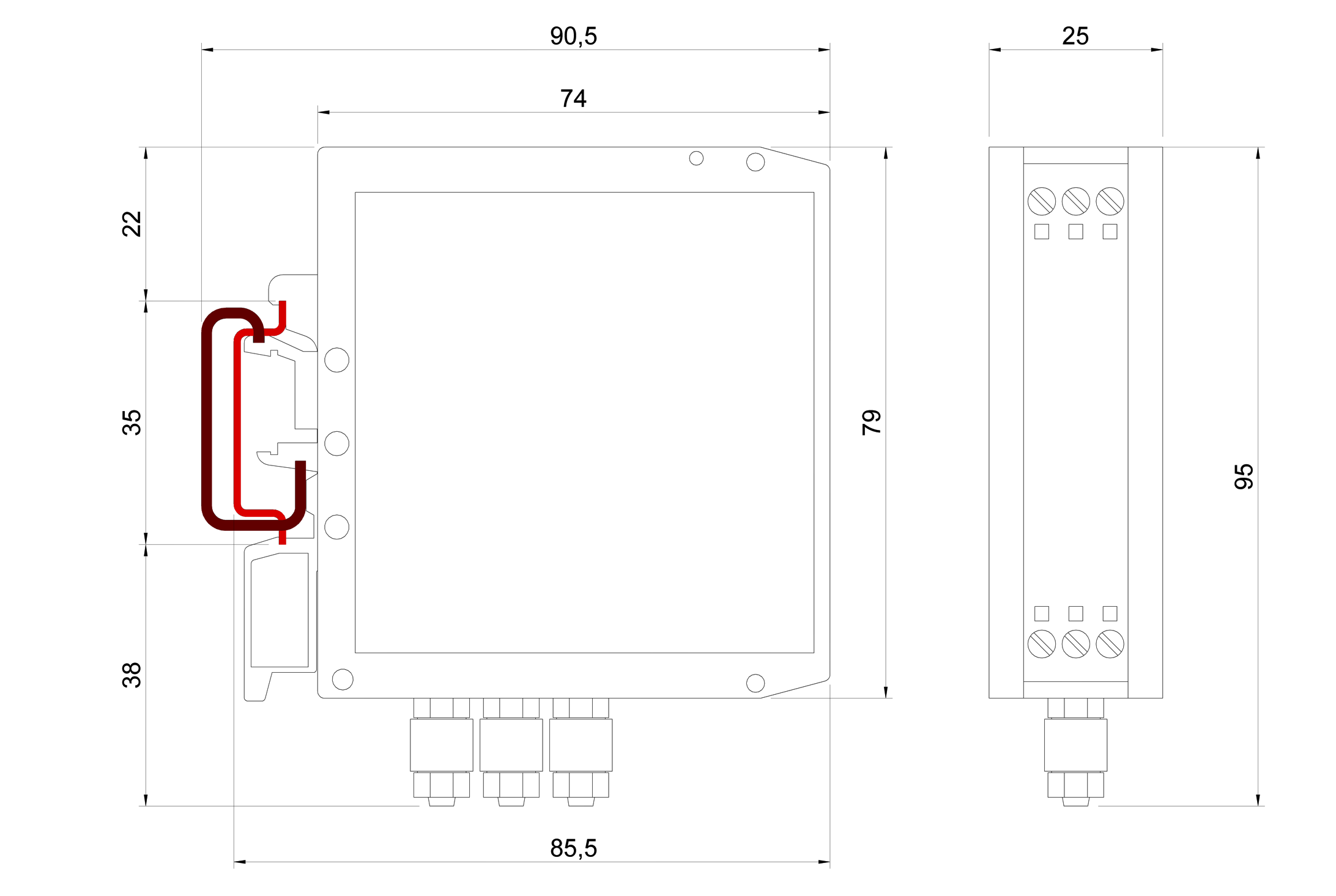

The controller is isolated from the vessel’s area and includes a gauge type pressure sensor, an airflow regulator with pneumatic adaptors, a calibration button and a status LED. It is designed to be installed inside an electrical control panel, snapped onto commercially available DIN mounting rails (NS32/NS35). The thermoplastic housing (Polyamide PA 6.6) is suitable and approved for electronic devices and industrial environment.

Features

|

|

Advantages of Bubbler Systems

|

|