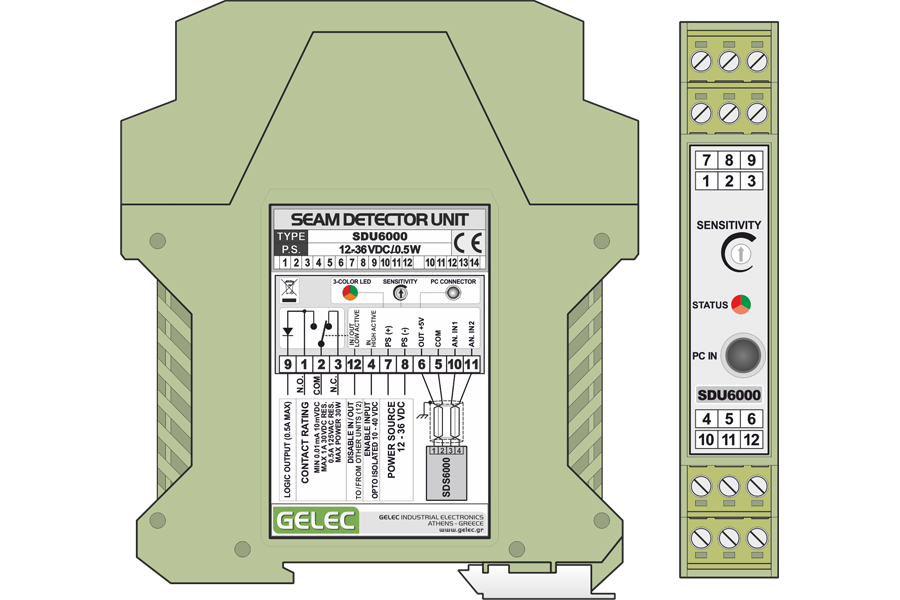

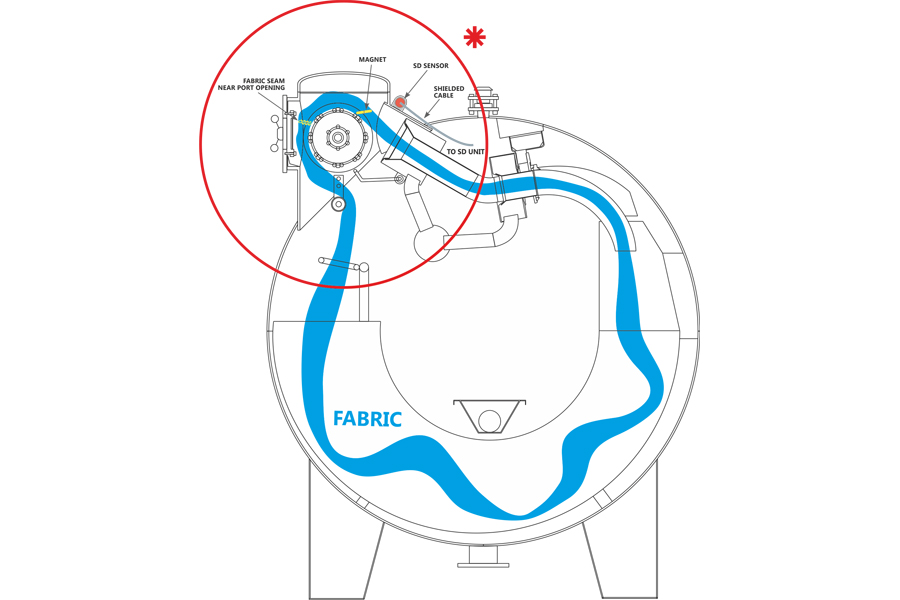

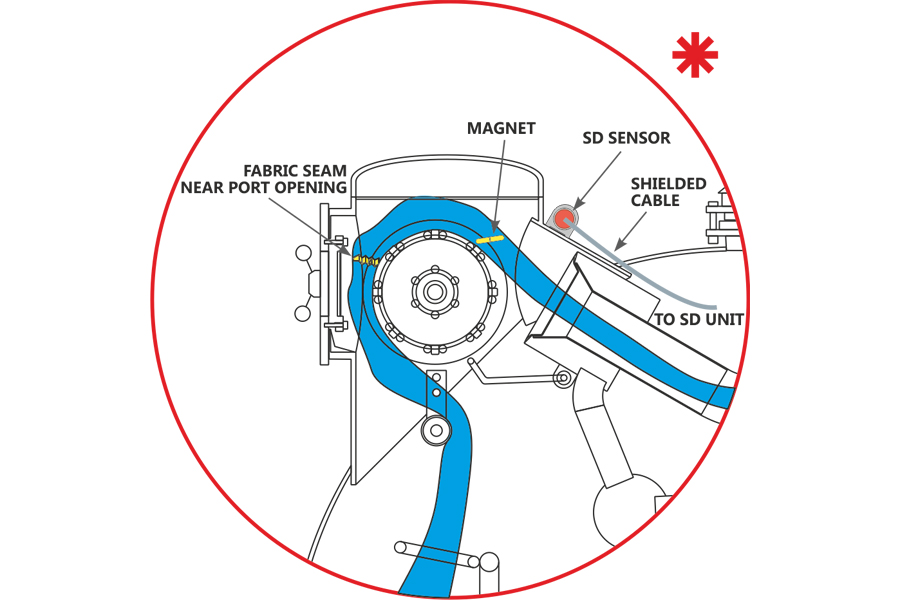

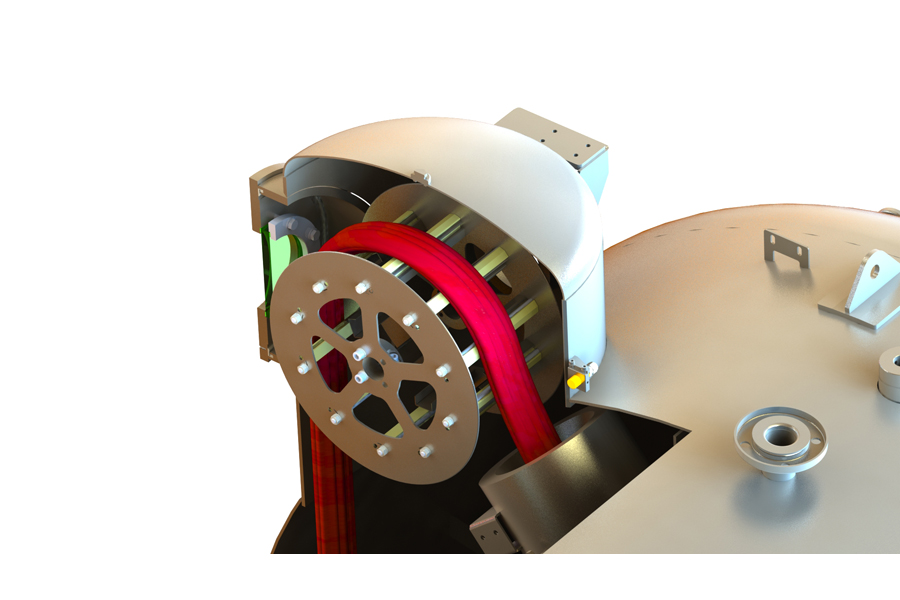

Seam Detector Unit SDU6000 is an electronic device, which detects fabric seam passages in fabric dyeing machines. Its sensor, mounted externally near the machine chamber opening, is triggered by the passage of a magnet which is sewn into the fabric rope, close to the seam. When a seam passage is detected, the device’s relay output is activated for further utilization and optical indication is also provided by the on-board LED.

SDU6000 is designed and manufactured to automatize the difficult and time-consuming task of manual seam searches on fabric ropes. The SDU6000 executes this procedure automatically, informs the main controller about the seam passage for any selected procedure, or/and stops the machine, placing the seam close to the chamber opening.

The use of SDU6000 decreases unloading/sampling time and therefore increases productivity. Dyeing process supervision and control are also improved by utilizing the provided signals and features for passage based procedures. Fabric damage due to sampling is also minimized, as the samples can be collected from the same point of the fabric rope.

It can be fitted to any type of fabric dyeing machine (Atmospheric, High Temperature etc.). A sensor has to be mounted near every chamber opening, close to the fabric path. The optional front panel indication device SD Monitor SDM6000 provides the necessary information about seam passages and when the machine stops, it indicates the corresponding channel number where the seam is detected. A series of compatible sensors, accessories and features are available for fully customized applications.

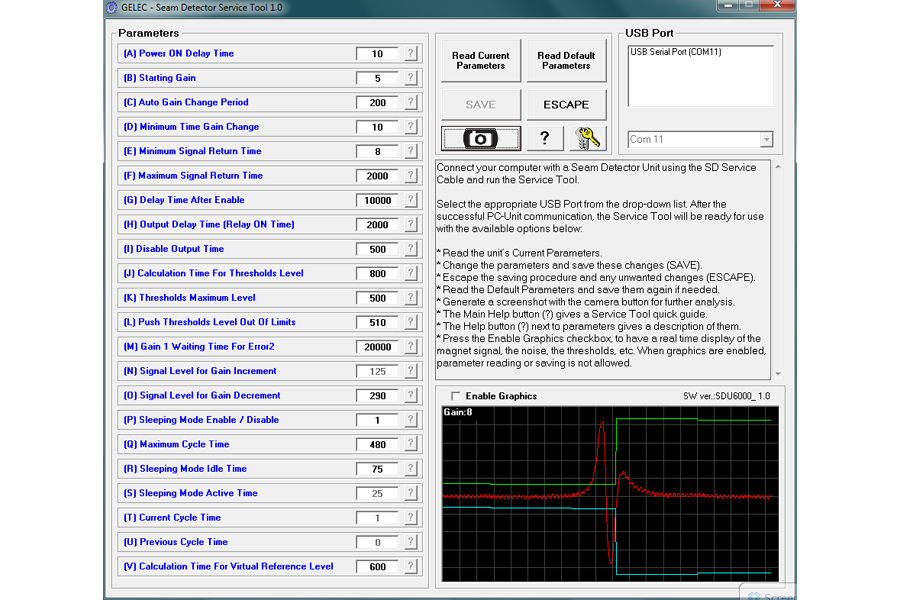

SDU6000 has a PC input for communicating with the SD Service Tool, a diagnostic PC software, which provides real time visualization of the sensor signals, electrical noises etc. It also allows the engineer to make adjustments in several device parameters. This analysis and monitoring gives a complete overview of the application environment and maximizes the SDU6000 functionality, solving detection problems in very demanding applications.

Features & Benefits

|

|