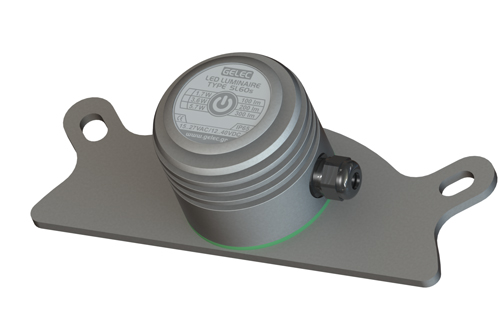

The incorporated LED module with a 50o lens provides efficient and high intensity illumination with low power consumption and can be power supplied with either alternative or direct current (AC/DC). It is equipped with an overheating protective function through an internal temperature sensor, which leads in intensity decrement or even in deactivation of the luminaire. Incorrect polarity and overcurrent protections are also available. It is available either with, or without on-board time switch.

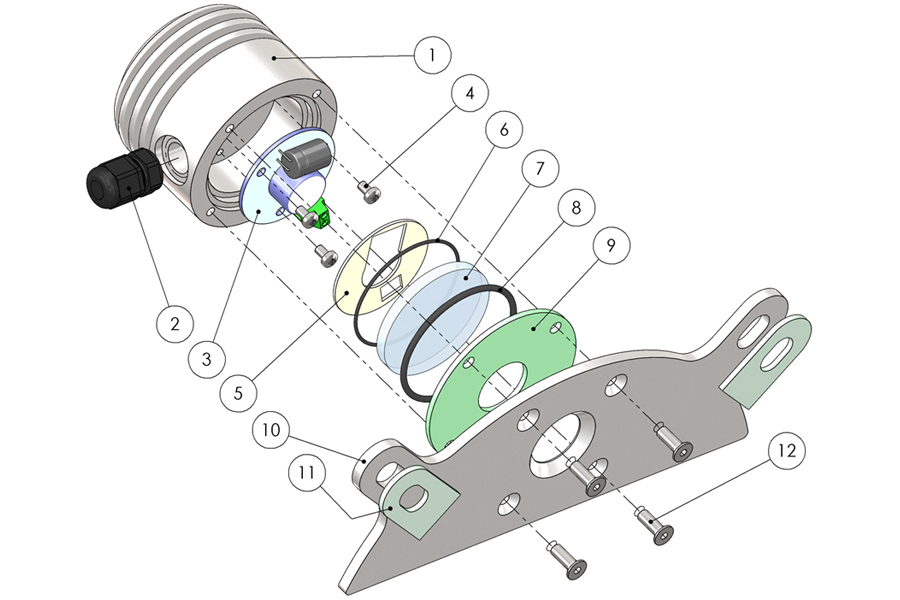

Manufactured from sandblasted stainless steel, it is designed to fit in any sightglass with the appropriate adapting flange and has a variety of mounting positions according your needs (position on the sight glass, cable gland direction, different or customized types of adapting flanges). It is dust and waterjet proof (IP65) and appropriate for high temperature applications, having a specific ‘heatsink’ design for better heat dissipation.

OPERATING MODES

The SL60s has an onboard tactile time switch with two operating modes available, CONTINUOUS MODE and TIMING MODE.

In Continuous Mode the luminaire lights continuously. In Timing Mode, the operator lights the luminaire for a given time range of 5 minutes and then it switches off automatically. In this way the LED module life time is being extended, resulting also an economic benefit from the reduced power consumption of the luminaire.

Timing Mode is enabled with an instant press of the button, while Continuous mode is enabled with a continuous press of the button for 3 seconds. To confirm that Continuous Mode is enabled, the luminaire flashes 3 times.

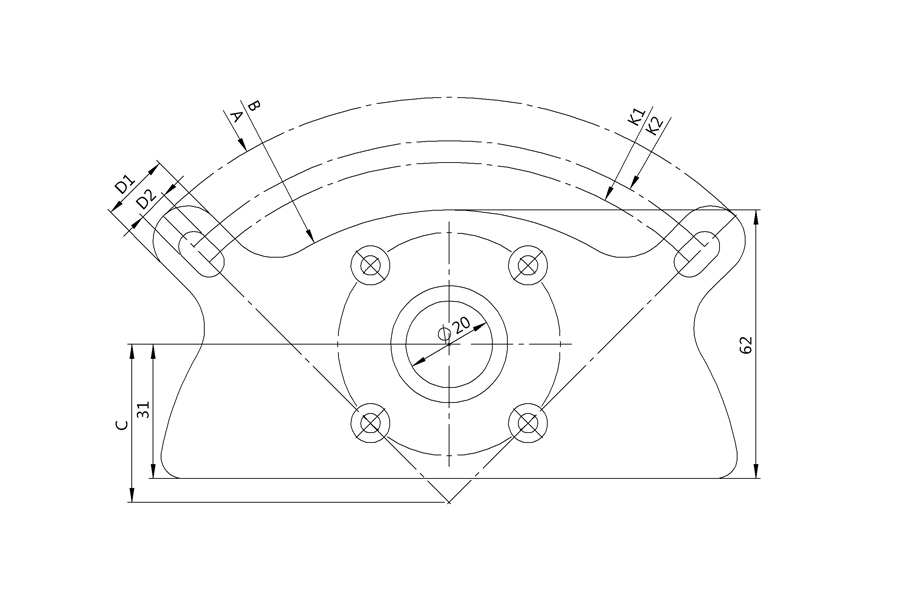

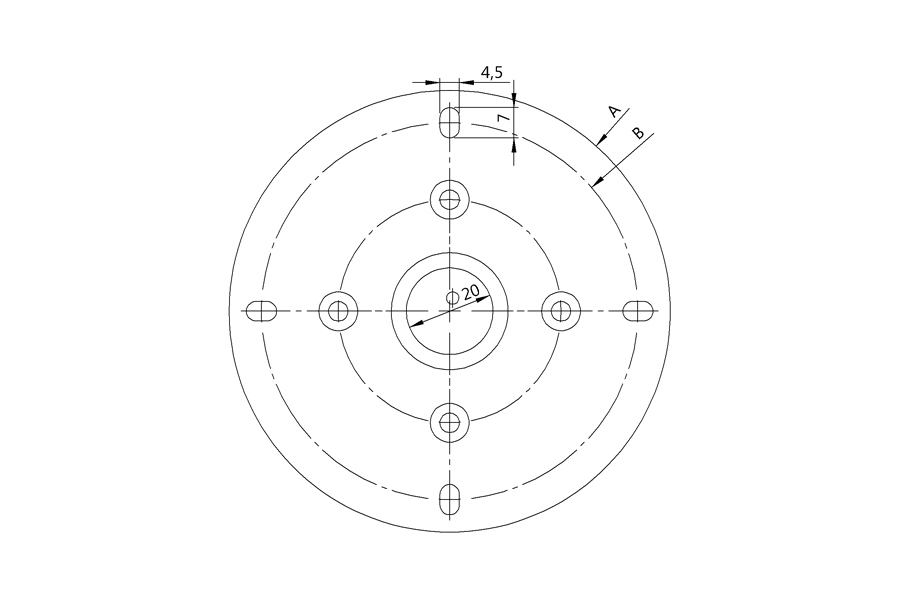

ADAPTING FLANGES

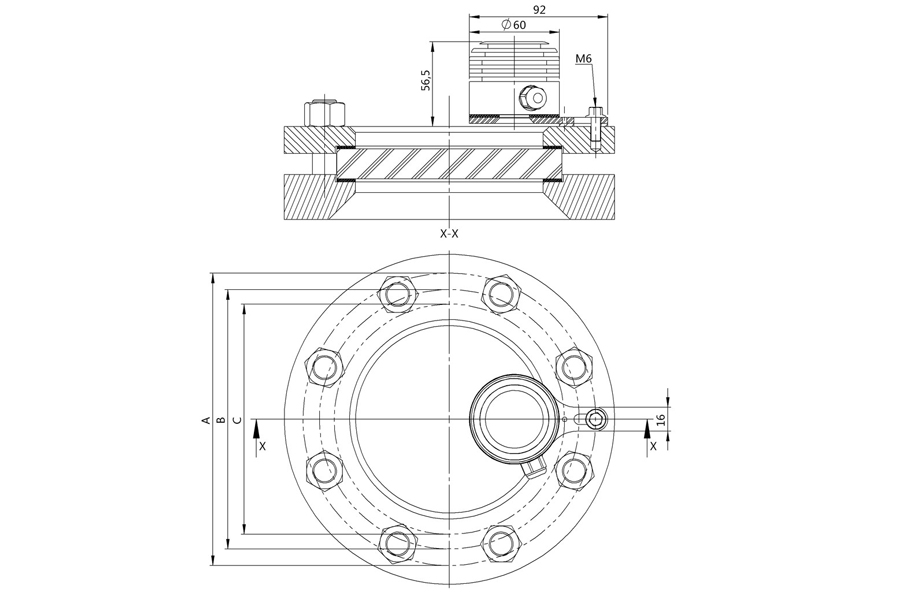

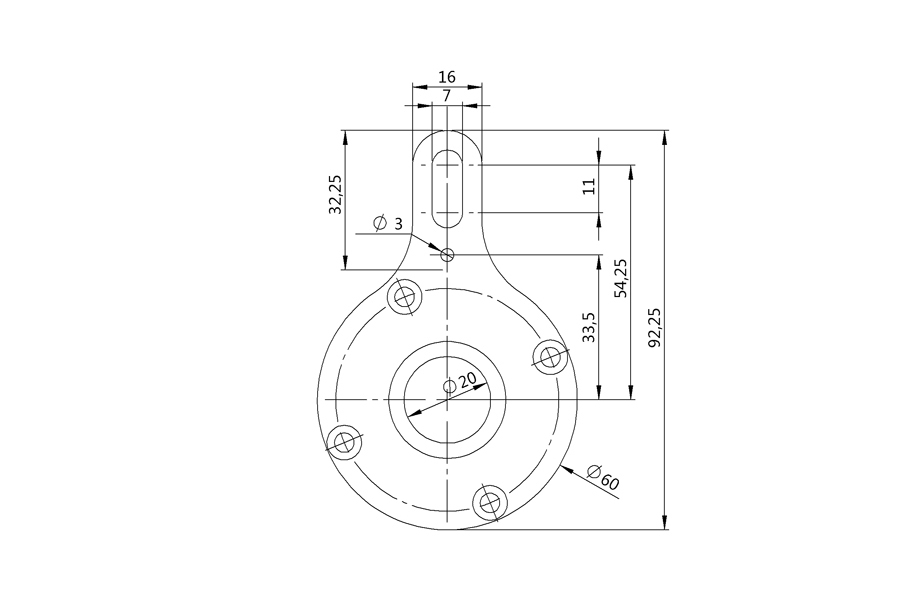

Sandblasted stainless steel (AISI 304) adapting flanges are the mounting component between the luminaire and the sightglass. Permanite sealing gaskets waterproof the luminaire housing and provide thermal insulation from the vessel’s temperature, giving the ability to use the luminaire in difficult industrial conditions. A countersunk hole allows proper light emission.

There are several types of adapting flanges available. You can find in the luminaire documentation the proper types for each sightglass standard and their detailed drawings. These adapting flanges can also be used at numerous applications and for different DIN standards (flow indicator sightglasses, rectangular or D-ended sight glasses etc.). Customized adapting flanges are also available upon request.

Features & Benefits

|

Applications

|